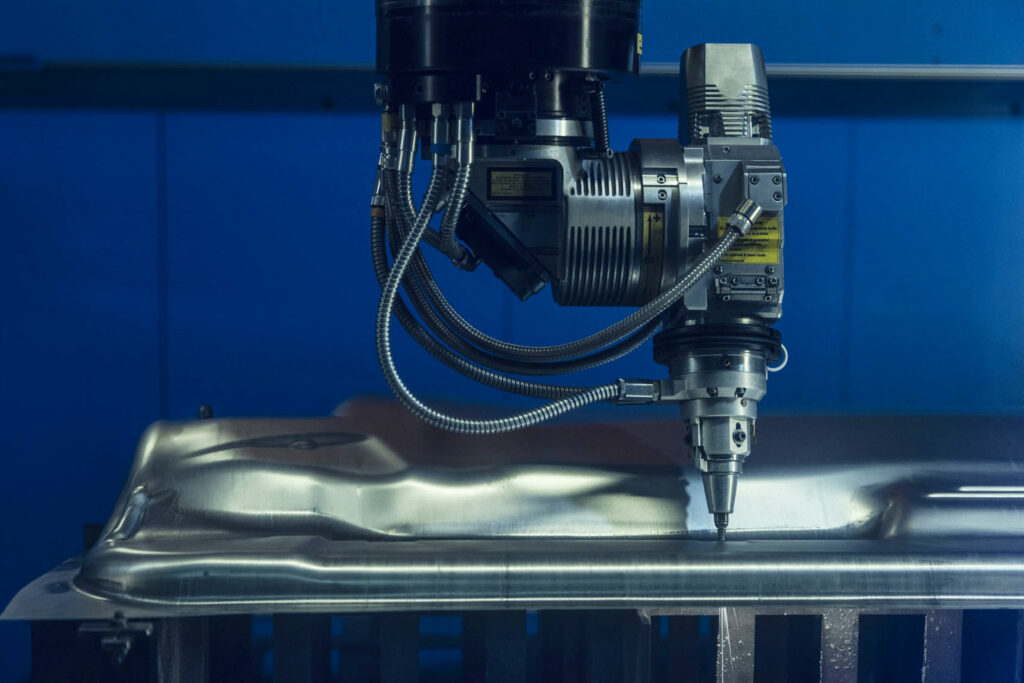

When it comes to meeting customer requirements, technological equipment can make all the difference. For 2D and 3D laser cutting, we have the most advanced equipment available, enabling us to carry out complex machining operations and layouts on steel and aluminium sheets, quickly and with maximum precision.

For any sheet metal processing, we have the best technology.

- Trumpf 2D laser up to 4000 W (1500 x 3000)

- Trumpf 3D laser up to 3200 W (4000 x 3000 x H1000)

We machine large sheet metal parts