We specialise in sheet metal die design, which consists of the design and manufacture of dies used for cold forming of metals. This is a complex process that requires experience and attention to detail, as well as knowledge of the behaviour of sheet metal during stamping. The precision of a mould affects, in fact, the quality of the moulded part.

Sheet metal mold design

Mould design: technology, skills, experience

- Mould design: new moulds based on customer ideas

- Reverse engineering: mould digitisation from finished product

- Gauge design

STA continuously invests in innovation and the acquisition of new skills. The technological and training aspect, as well as the experience gained in the development of complex projects for many sectors, guarantees an advanced design capability and is an added value in terms of cost and time savings.

Custom mold design

Economic and feasibility analysis

For STA‘s designers, the first step is to fully understand the client’s needs and identify any peculiarities and criticalities of the project.

Co-design

We share design ideas, define every detail with the customer and guide them towards the most functional solutions. Our in-depth knowledge of production and assembly techniques allows us to have a comprehensive view of what a mould of excellence should look like.

Regular confrontation and sharing with the customer

The flow of ideas is constant between us and the customer: the collection of information and feedback, as well as our advice on optimising the final mould, enable us to fully meet the customer’s requirements.

Advanced mould filling and simulations

Simulations are essential to optimise the mould geometry and guarantee the quality of the final part. Mould filling simulation software allows us to study the moulding process in advance, obtaining valuable information to optimise the production cycle and reduce delivery times. At this stage, critical issues can be identified and corrected before moving into production.

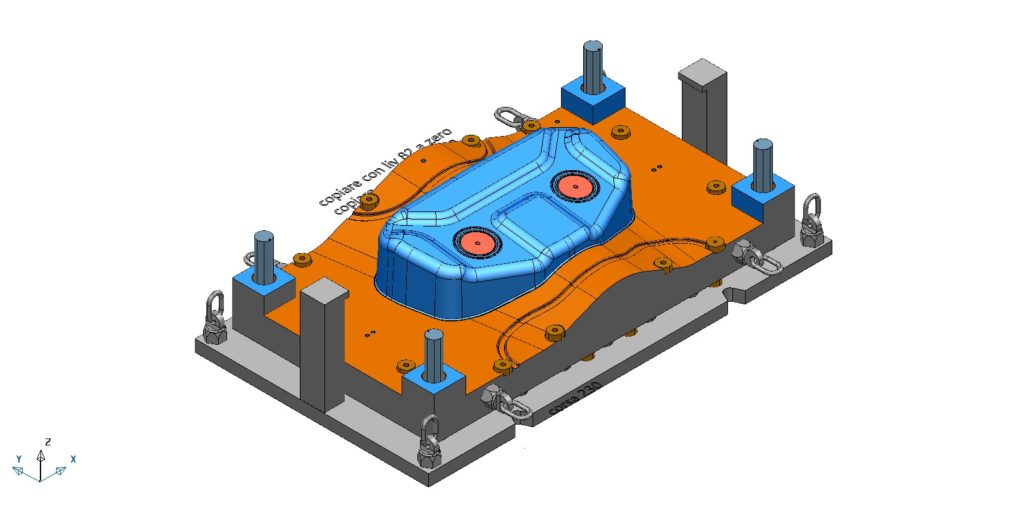

3D design

Our technicians proceed with the three-dimensional design of the mould using sophisticated CAD CAM software. At this stage we proceed to the development of the details for a precisely tailored mould.

Other software used in the design phase: Autodesk CAD, Autoform, Dassault Catia, Siemens NX.

Accredited supply networking: we reduce time to market

STA can count on a supply network selected over the years that allows us to drastically reduce the ‘time to market’ and guarantees the efficiency of this first project phase, developed as a single service to the customer or as the basis for the development of all subsequent processes.

Specialists in complex shape molds

Our machine shop is equipped with a fleet of NC milling machines that allows us to make any sheet metal deformation mould, and to carry out any mechanical machining required.

As a guarantee of maximum production flexibility and compliance with the highest quality standards, we have obtained certifications that meet the main international guidelines

We design dies for sheet metal forming

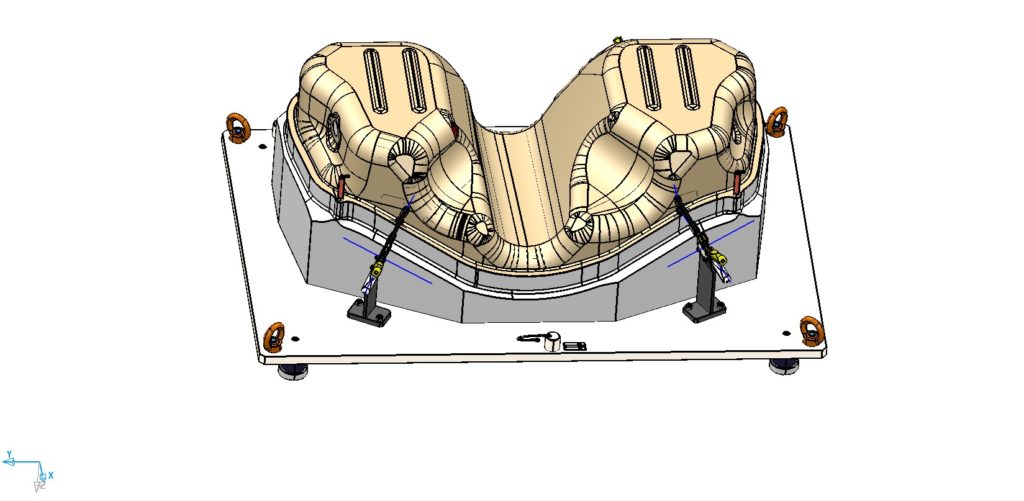

Deep drawing molds

When the customer needs to achieve deep sheet metal deformation, what is needed is a deep-drawing die. The die is pressed onto the material, which is stretched or compressed, without a change in thickness. With this type of mould, three-dimensional shapes are obtained that are useful for sectors such as furniture, automotive, medical industry.

Progressive dies

These tools are required when sheet metal forming requires several work steps. The sheet metal is selectively deformed with each pass under the press according to a precise sequence.

Bending and folding dies

For shallower deformations or for bending materials such as sheet metal or tubing, in a precise and repeatable manner, we design bending and bending dies.

Transfer molds

The continuous research and development of moulds to optimise the machining of a workpiece has made us experts in the design of transfer moulds. The peculiarity of these moulds is that they allow the workpiece to be machined with different positioning within the same machine.

We design moulds for all companies

We design moulds for all companies that need to shape their products and produce high-precision details:

- AUTOMOTIVE

- EARTH-MOVING MACHINERY

- HOUSEHOLD APPLIANCES

- AEROSPACE

- FOOD INDUSTRY

- FURNISHING

Reverse engineering: from mold to 3D model

The reverse engineering service is dedicated to customers who wish to derive data for a project from an existing product.

The Reverse Engineering process consists of digitising the mould by scanning the physical object with special systems (laser and photogrammetry) to obtain a reliable and replicable 3D CAD model.

This procedure is extremely useful if the mould is old and not accompanied by 3D files or technical data.

The main advantage of reverse engineering is the reduction of design time for the new product, thanks to the digital model created.

Gauge design

We produce gauges in aluminium, resin and, thanks to the use of 3D printers, plastic.

These measuring instruments are used to check the dimensions and geometries of moulded parts, ensuring that the required tolerances are met. As with mould design, gauges require an in-depth study that starts with a technical feasibility analysis and the definition of the gauge requirements.