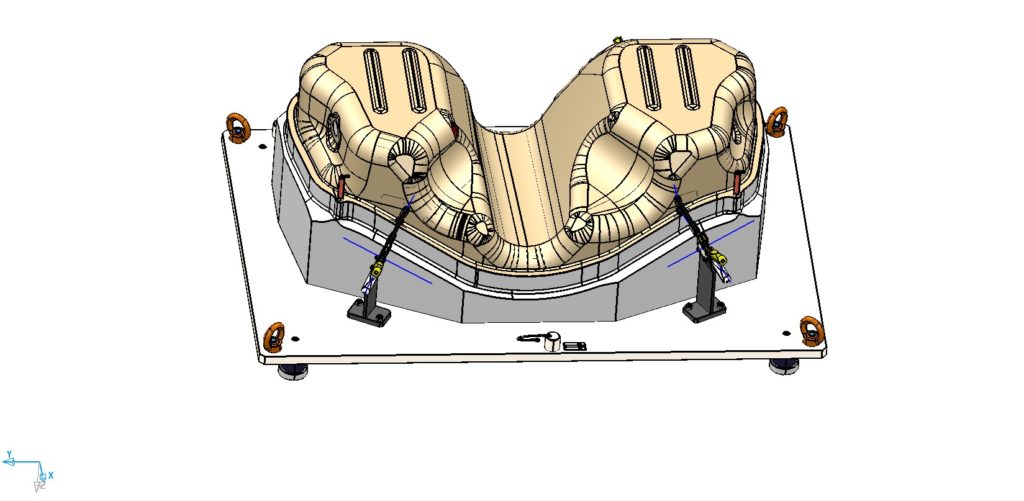

After sharing and analyzing the customer’s ideas, our technicians proceed to the design and dimensioning of molds and components.

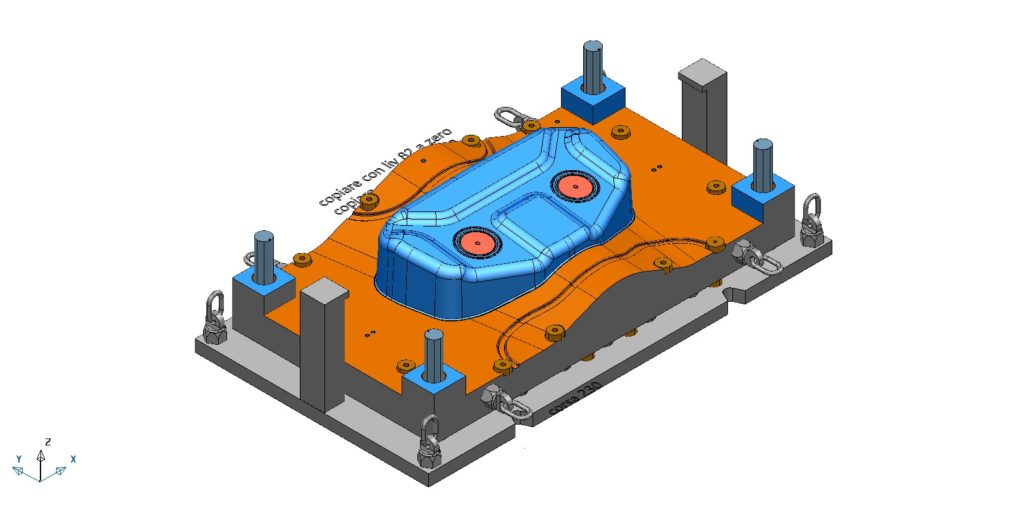

Mold filling simulation software allows us to study the molding process in advance, obtaining valuable information to optimize the production cycle and reduce delivery times.